Engineering Support

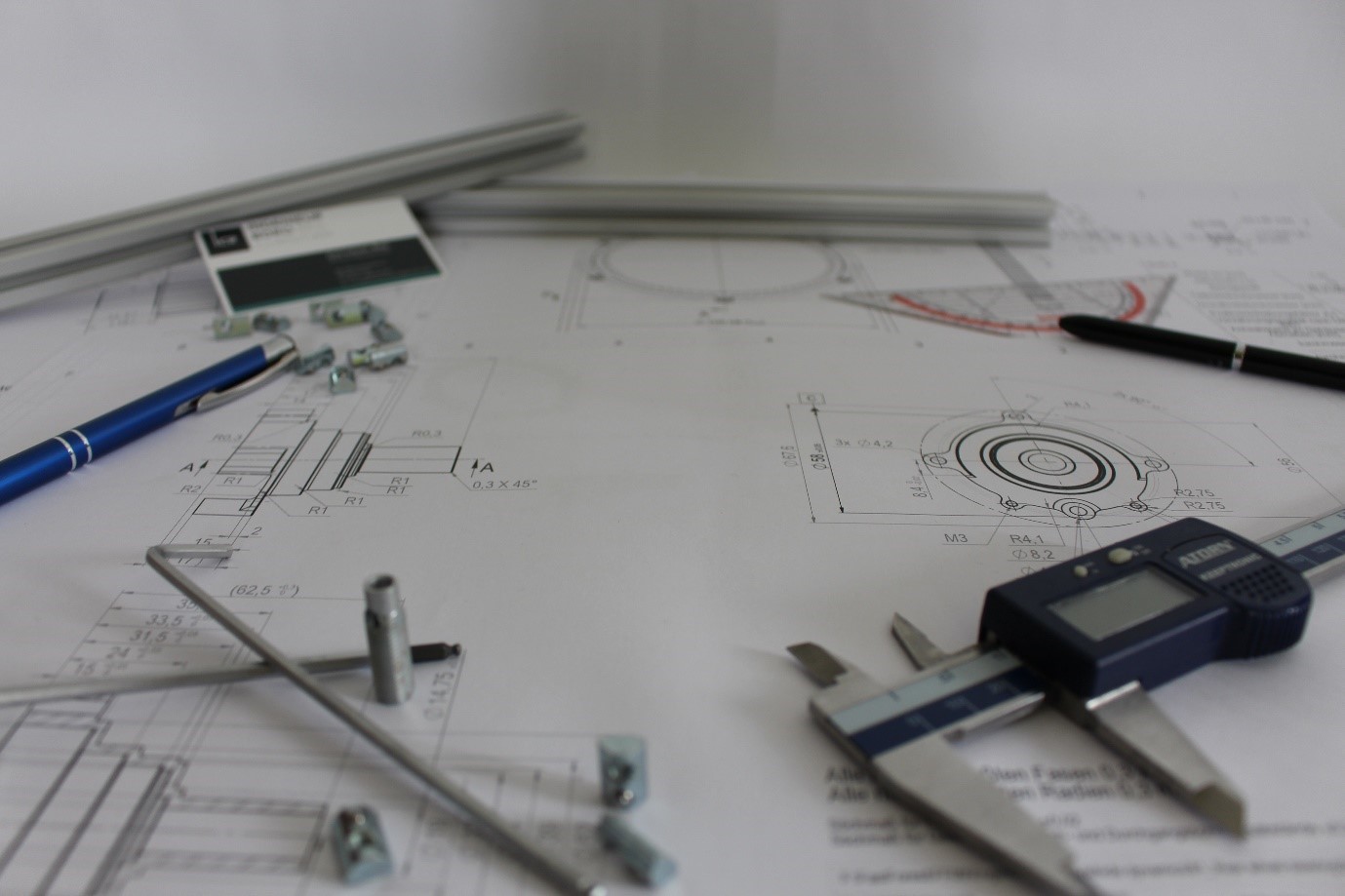

SATH maintains a full range of advanced technology and modern fabrication equipment to perform all services in-house. From design to delivery, we provide one-stop precision manufacturing and align our practices, policies, and production with global standards.

Over the decades, manufacturers have produced millions of machine parts and components that sooner or later tend to break down. When a part malfunctions, you want to replace the component, not the entire device. Unfortunately, many older parts are no longer available. Our engineering service makes replacing these parts possible.

Producing a custom metal part in a specific desired shape requires specialized fabrication equipment. We use a variety of tools for metal fabrication such as CNC machines, laser cutting machines, and water-jetting machines. At SATH, we have the materials, machinery, and experience to handle any custom metal fabrication project.

Our fabrication services include the building of metal parts by laser cutting, water cutting, bending, CNC punching, shearing, forming, hardware installation, spot welding, MIG or TIG welding, metal finishing, and machining requirements. These processes are performed using specialized equipment (often created for a specific application), expert technicians, and/or multiple machine operations.

Working with SATH ensures that your parts are made specifically for your application. We have facilities equipped with the latest machining and fabricating equipment—welders, millers, CNC machines, and more.

Along with state-of-the-art equipment, you receive the highest quality materials. If you’re unsure of the best metal or alloy to use for your project, our team has the expertise to guide you in your selection. We understand the nuances between alloys and how they perform in various environments and applications.

We stock a wide variety of special grades and alloys of steel, aluminum, and stainless steel sheets, plates, tubes, and bar stock to help ensure a quick turnaround for your projects. Our experienced metal fabricators can complete most custom metal fabrication projects in two weeks or less. Our goal is to provide the customized metal manufacturing our customers need—all from one metal fabrication shop.

CAD DESIGN

CNC CUTTING

welding

laser cutting

assembly fitting

bending

gearbox service

manufacturing components

obsolete parts

prototyping

pump repair

punching

reverse engineering

value engineering

valve overhaul

0

CREATIVE VISION

SUCCESSFUL PROJECTS

0

STRONG RELATIONS

LOVELY CLIENTS

0

+

PERFECT TEAM